Jingcheng Machinery Manufacturing Co., LTD., uses the latest technology developed which can work out high quality stick noodles in in any weather conditions, low temperature noodles drying line.

Equipment structure and technological process of Dried Noodles Making Machine

One, flour mixing system. It is the first working procedure noodle production, the purpose is to add right amount of water in flour and other accessories, agitate the protein in wheat flour water absorption expansion, with toughness, elasticity, viscosity. The device has a single shaft mixer machine, biaxial mixer machine.

Two, dough rolling, cutting system. Curing machine, compound machine, rolling machine, cutting machine, rod supplying machine, hanging machine six part together complete noodle forming stage. And good curing after 10 minutes, stirring of grains to make fully absorbing water, puffing formed wet gluten and made into composite rolling machine, press dough sheet to 0.8-0.2 mm. Through cutting knife, according to the different specifications of wet noodles cut into 0.8 to 3 mm, rod supplying machine put 2400-2600 - mm long noodles by hanging machine up to parallel chain stores.

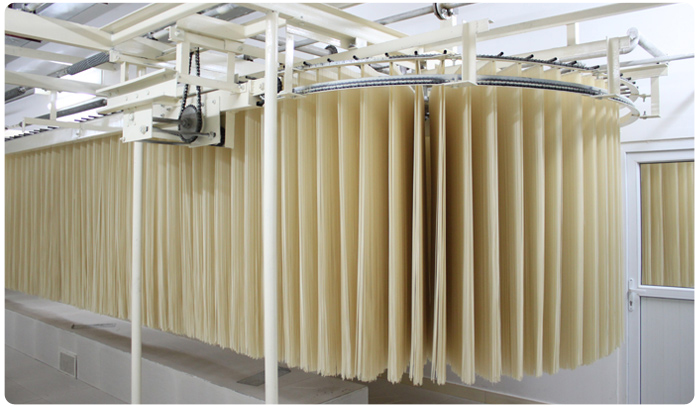

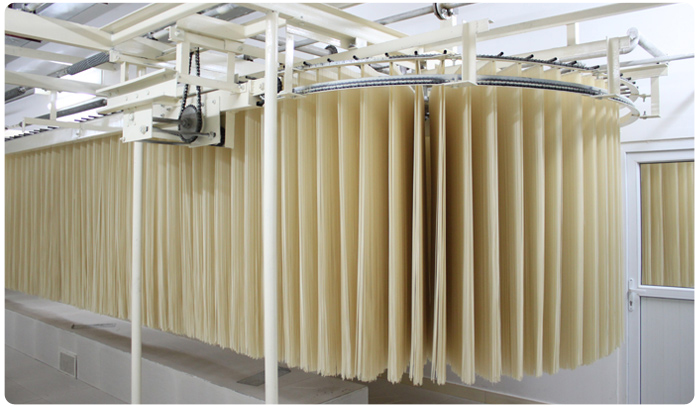

Three, automatic shelves end tail cut tidy device consists of hanging, trim noodle ends, cut, control cabinet. Noodles hung on steel bar are lifted to starting point of drying room, using integrated circuit control. Synchronously hung on hanger of mobile drying device, end cutting machine costume on the starting point in the process of drying, cut down the noodle end for recycling use at any time, due to cut into a certain length in advance before entering drying process, greatly reduced cracker dough head.

Four, drying system. Drying system consists of drying operation main drive, steel structure of the cooling fan, moisture removal fan, steam heating tube, sensor, the temperature and humidity detection control instrument, electrical control and so on,

Five, putting-down production system. This system consists of the putting-down parts, finished product tidy machine, cutting machine, control cabinet and so on, after 4 to 5 hours to dry.

Ralated Product:

3T/8H Chinese Noodles Production Line

Our Service

We sincerely supply comprehensive and best service to all of our customers. We offer services for the following.

1. supply solutions for the buyers' special demands

2. new design plant layout according to the actual situation

3. onsite installation, commissioning and operational training

4. provide technical support both at setup and maintain

5.

long - term supply of spare parts

6. warranty service

About Us

JINGCHENG Machinery Company set up in 1988, is a

professional manufacturer and exporter of different noodle making

machines.Our company offers complete sets of fried instant noodle

production line and non-fried instant noodle production line, dried

noodle production line,fresh noodle production line, corn noodle

production line and rice noodle production line. As a result of our high

quality products and outstanding customer service, we have gained a

global sales network . The products of our company are exported to many

countries in Asia, Western Europe and South Africa.

Contact us now! To get more information about noodle production!

Contact us now! To get more information about noodle production!